AT&T technicians take pride in the high quality work standards they are trained to meet and deliver to customers. The nonunion contractors that AT&T increasingly rely on to build its broadband network often fail to meet the specifications and standards demanded of the company’s direct employees. When deployment work is subpar the negative outcomes fall on customers, localities, AT&T technicians, and the AT&T brand. The survey results described below suggests that substandard contractor work can lead to delayed deployments for customers, field operations inefficiencies, including the re-doing of already-paid-for work and redundant truck rolls, and high amounts of stress for technicians leading to burnout, which can disrupt critical workforce staffing. As one AT&T employee responded in the survey, “It’s a defeating feeling when we are told to follow CODE in our organizations, but contractors don’t adhere. Care, Own it, Deliver, Exceed expectations.”

AT&T introduced the CODE initiative in 2019 to provide a framework to empower its field technicians to make good decisions that best serve the customer. AT&T believes that field operations are a crucial part of the customer experience.[20] Customers expect to know when their technician is going to arrive, how long the job will take, when they can expect service to turn up or resolution of their issue, and that their residence will be cared for properly by the technician. To help achieve this goal, AT&T introduced its Dispatch Learning Engine in 2018 to optimize schedules for its techs, minimize drive time, and maximize the number of jobs they are able to see everyday.[21] Yet, the survey results suggest that AT&T’s nonunion contractor workforce may be undermining the company’s efforts to be as efficient as possible.[22]

Seventy-seven percent of survey respondents report being impacted by contractor quality issues at least weekly, with more than 1 in 3 experiencing a daily impact. Describing one of their biggest concerns about the quality of work done by contractors, one respondent said,

“You cannot substitute for experience. It takes many years to be good at this job. You cannot just hire the cheapest contractor to do the work. It shows everyday, to us technicians and to our customers, that AT[&]T is cutting corners on quality.”

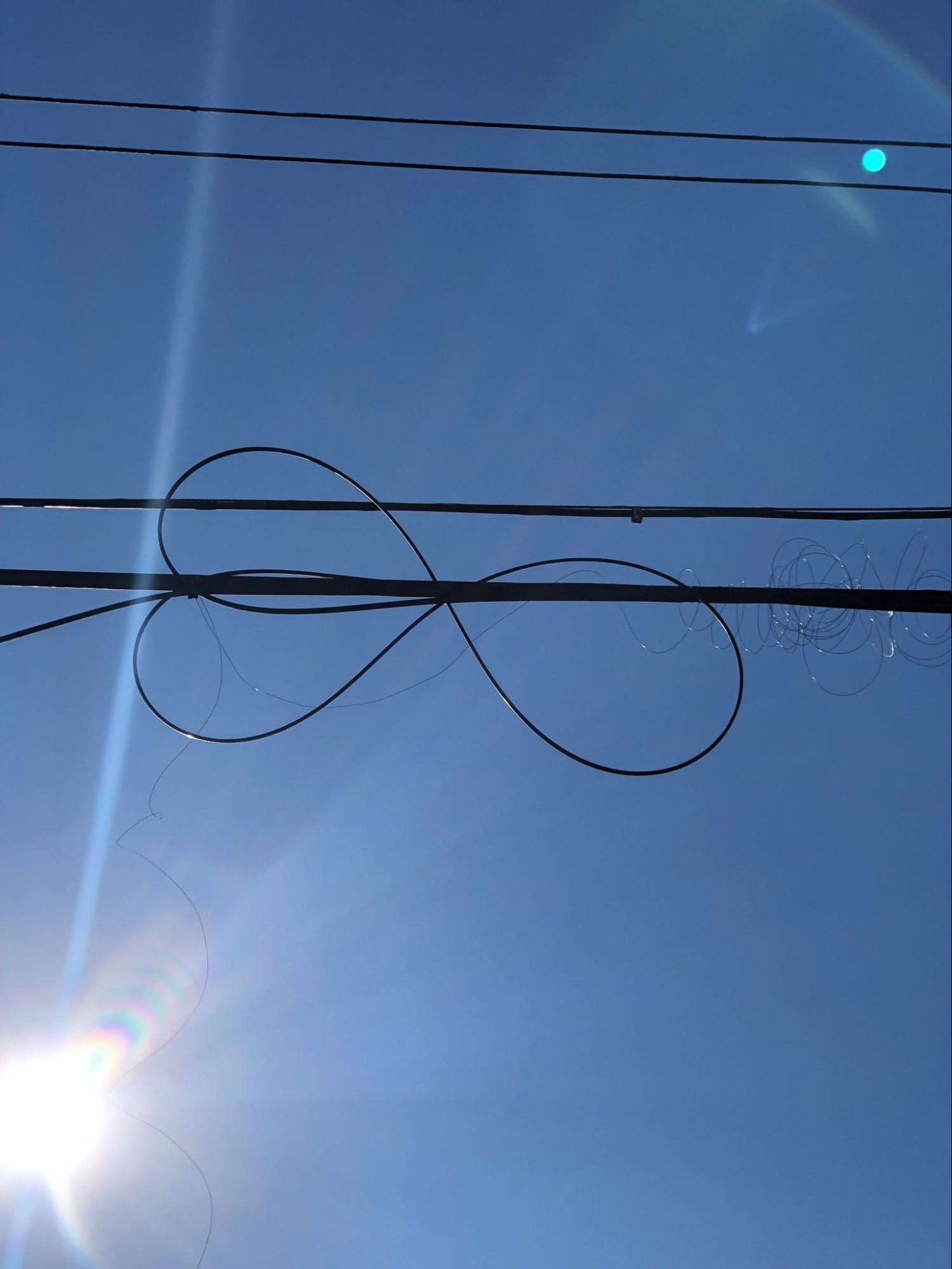

Technician reports of shoddy or substandard work quality by contractors cover a range of problems that can lead to the unnecessary or premature degradation of the network, damage to rights-of-way, service disruptions, or dangerous conditions for workers and the public. The shoddy work reported in CWA’s survey of technicians includes: disruption of already-active above ground service lines, underground utility strikes, improper placement of network infrastructure in the right-of-way or on customer property, failure to install critical infrastructure components such as terminals, lack of sealing to protect network infrastructure against external elements, safety issues arising from improper grounding or bonding of the network, and failure to restore customer premises to original or improved appearance.[23]

AT&T technician respondents report delays and inefficiencies in the use of their time and company resources resulting from shoddy contractor work. Asked about their biggest concerns regarding the quality of work carried out by contractors, based on direct experience, a respondent said, “Poor craftsmanship causes jobs to be delayed and possible missing of commitment dates. It can also put the public, technicians and contractors themselves in unnecessary harm's way. It costs extra money because when the technician has to take time to correct contractor issues the company is paying twice for the job to be done.” The survey bears out these comments:

- Sixty-five percent of respondents reported having to re-do contractor work because it was not up to standard.[24]

- Similarly, more than 65% have had to return to job sites more than once to address problems related to poor quality contractor work.

- Nearly 80% say their work assignments take more time to complete than they should, as a result of contractor quality issues.

As one technician noted,

“The company’s numbers game doesn’t account for the amount of returns that each tech has to do because of [shoddy] work.”

Survey respondents emphasized that direct employees are required to oversee and re-do contractor work on a regular basis: “We have to be on site the whole time the contractor is working just to make sure that job is done correctly. If you're not there when work is being done you have to recall [the] contractor to dig back more or they exposed [the] wrong cable.” Another respondent noted the delays caused by contractor errors, stating “Yes most of the time we have to put a job on hold due to contractor errors. It usually take[s] a week or two for a contractor to get back to a job when they have moved on.”

“I’ve had to do engineering work to design fixes for botched jobs installed by unsupervised contractors installers because the engineer lets contractors do all the designing of the jobs without the engineer even visiting the sites. Causing poor installs of equipment and facilities.”

Survey responses indicate that contractor quality issues appear to be recurring and consistently falling into preventable categories. Seventy-five percent of survey respondents reported encountering “Placing Issues” and another 66% reported encountering “Terminal Issues.” Placing and Terminal issues include problems such as improper placement of cables and network equipment on customer premises, leading to jobsite revisits, preventing the turning on of service at scheduled times, and delays in network quality testing. Further, 44% of respondents reported encountering “Ground or Bonding Issues,” which include failing to properly ground cables, which can introduce unnecessary electrical hazards, and can lead to risks of electrical shocks for technicians and customers, as well as risks of fire. The photographs below illustrate the placing, terminal, grounding, and other common quality issues resulting from substandard contractor work identified by AT&T technicians.